What Is Spare Parts Inventory Management and Why Ignoring It Costs You Millions

Businesses that rely on spare parts know that spare parts inventory management is of great benefit.

Any industrial or commercial setup would require an organized space where all the equipment spare parts are kept, and they are accessible at once when needed.

In modern times, there are numerous software applications in the market that automate the process of tracking and managing these spare parts.

Things like inputting, storing, and tracking the parts should be the primary focus of the software solutions. Additionally, these also offer dashboards to understand the usage of spare parts and determine the places where usage is due to poor management and where there is low stock, compared to the requirement.

Managing an inventory might look simple and can be done through paper and pen in a small business. However, if we take the example of a big industrial setup with multiple branches, managing spare parts inventory is a big deal.

Here, the business needs a solution where all the inventories are united, and a consolidated view is available. This will help the business track all at once, and never miss a stock refill or over-usage of the same.

So, what is spare parts inventory management, how does it work, the core principles, and some hacks to better manage without consuming many resources?

Before that, let’s briefly take a look at,

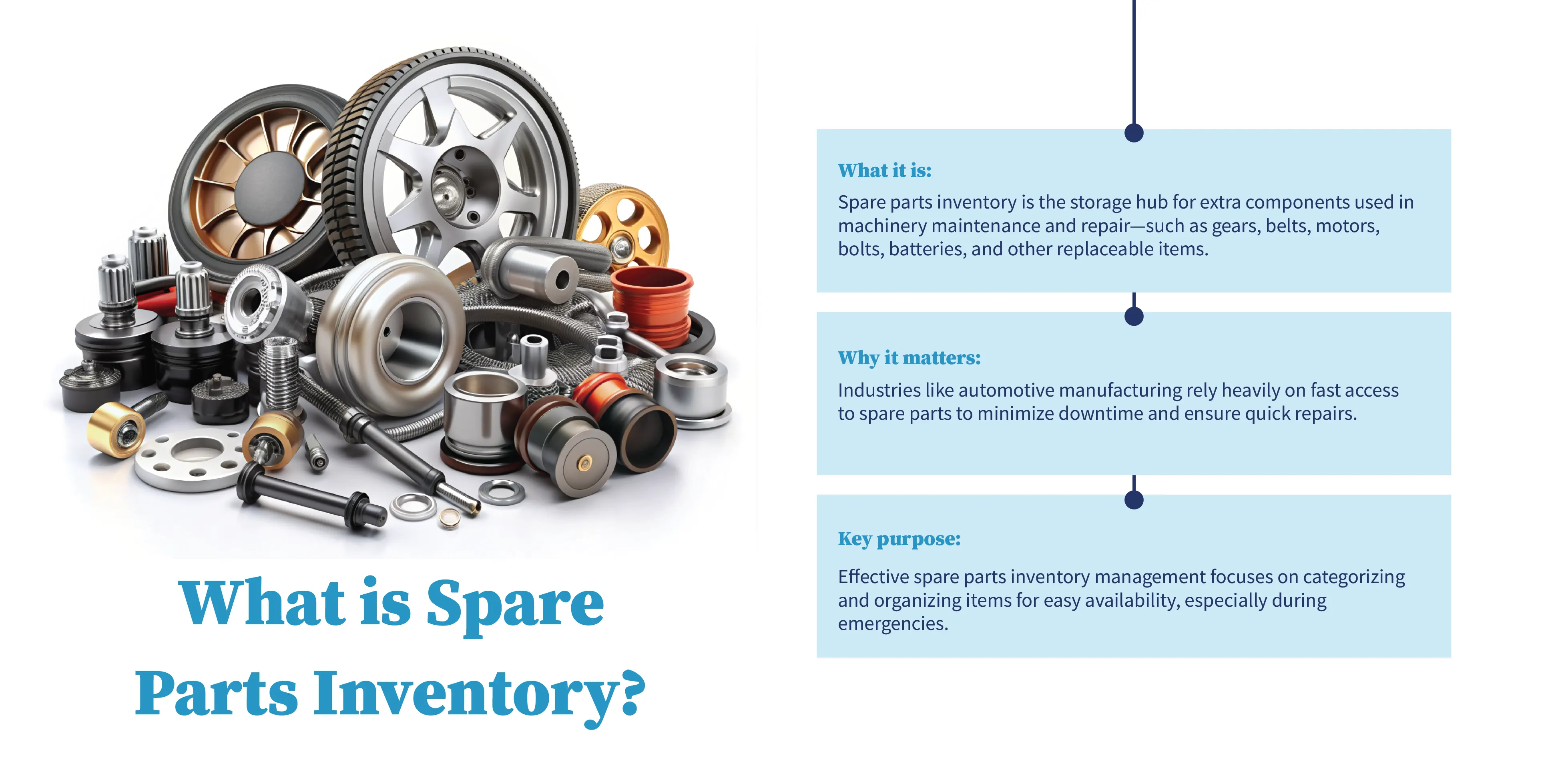

What is Spare Parts Inventory?

Spare parts inventory is the space where all the extra parts of various machinery are kept. Technicians use these parts during maintenance and repair; the items may include gears, bolts, belts, motors, and much more.

Automotive manufacturers have the most demand for the constant availability of spare parts and getting repairs done within a short time. Additionally, the spare parts inventory will also include other items, like robotic arm consumables, welding tips and nozzles, stamping die accessories, hydraulic and pneumatic seals, sensors used across assembly lines, conveyor rollers, and CNC tooling inserts that also require replacement after certain periods.

The categorization of these items, to keep them organized and available in cases of emergency, is what Spare Parts Inventory management aims for.

What is Spare Parts Inventory Management?

The management of the spare items, in a way that each part is categorized based on its type and priority.

Good quality management refers to parts being available on time, without causing any delays or disruption to the operations. There are basic to advanced levels of inventory management, and this depends on the solution you are using and your inventory scale.

For example, in several industrial setups, the repair or replacement of parts of certain machine parts requires immediate action. Any delay could harm the whole process, and hence, in such cases, effective management comes into play.

Items that require immediate availability should be kept handy and in front of other items. Inventory managers can do this by categorizing the items based on their priority.

There are more than one category to divide the items in an inventory, and ensure parts availability always.

Let’s look at the categories available to differentiate and manage spare parts effectively.

By criticality

Items that are not available will stop the entire operation. Such items should always be in stock, by meaningfully splitting them from the rest of the parts.

By Function

Parts associated with equipment should be categorized by their machines. For example, the mechanical parts of a particular machine should be kept aside from the electronic parts of other vehicles. Other instrumentation and control devices should also be kept separately from process-specific parts.

By Usage frequency

This is a critical step that will help businesses every hour of a busy production or operation day. Keeping the items that are required frequently at handy distances is always a good choice. While things are categorized based on their function and importance, their usage frequency matters a lot. Executing this point gives you the confidence to access spare parts within minutes of repair or replacement.

So, these are the most important categories that businesses must ensure to consider while segregating items.

Now, let’s see some ways to

Improve Spare Parts Inventory Management

Proper spare parts management is critical to seamless operations and consistent growth for the companies. Different companies have their own approach toward this; however, these best practices will suit companies across sectors.

Systematic identification of parts

Systematic identification of parts involves the following things to be covered. These are:

Creating barcodes for internal identification of parts and registering them in the system gives you more control over every movement of spare parts. Another hack to optimize stock levels is to maintain a proper Bill of Quantities and upload it to the asset maintenance management software for more detailed tracking.

Manage unused parts

There can be several instances where, during major overhauls or machinery failure, a lot of parts are needed. Now all of them might be used at that repair.

Here, what most businesses do is they keep the items in a cabinet or something for future use. However, no track remains of those items, which may result in buying of same items again.

Hence, such items should also be added to the inventory with proper records, ensuring that there is no loss in the procurement process.

Utilize and Manage Bills of Materials (BOM)

Just as BOQs, BOMs are equally important in managing spare parts efficiently. This is the ultimate source of truth for businesses to keep every spare part on track.

Procurements can happen as and when required, which will generate multiplier BOMs. Hence, the best way forward is to maintain a master BOM, where all the other bills will be added as they are generated. This is how you can track every part added to the inventory items with its quantity.

The current status of that stock will be visible in your inventory management system. Facility management systems like Innomaint offer advanced features to analyze and manage spare part inventory efficiently.

Maintain a Simple work order

Spare part usage can be made efficient with simple work order processes that can be followed across departments. Whenever a spare part is issued, the work order should be generated.

This will help keep track of inventory levels and maintain the right balance between overstocking and shortage, enabling minimum recorder alerts. The aim to keep this simple is because the work varies across departments, maintaining inventory accuracy.

There are departments where following a complex work order may be challenging for less timely availability. Employees may not follow the desired process, which would cause problems maintaining accurate inventories.

Centralized Inventory

When all the spare parts groups are consolidated into one part, this helps manage inventory better and perform clear inventory audits. The satellite parts should also be clubbed with the centralized inventory, and businesses should provide the responsibility to a core team.

This team will only have access to the inventory control system and can view all the data. By limiting access to the inventory and setting up a core team for inventory management, companies can reduce human errors and miscommunications.

Utilize an inventory management system

Everything will be streamlined once a business starts using the inventory management system. All the data regarding the current and previous usage of inventories can be uploaded there.

Many advanced systems today use Machine Learning (ML) and Artificial Intelligence (AI) to conduct deep analyses and provide actionable insights to reduce inventory costs. Such systems make cost tracking, managing, check asset performance and maintenance far easier, and at the same time ensure that there are no errors, and also help optimize inventory levels.

So, these were the chosen best practices among many that you can use to enhance your spare parts inventory management and get rid of excess inventory.

Now, the question is why you should not ignore the spare parts inventory management, and why that may cost you millions.

Why You Should Not Ignore Spare Parts Management

Inefficient inventory tracking generates hidden costs that are impossible to avoid. This is because the primary thing is not the availability of the backorder of the spare part.

In case of major hauls, if the part is not available or to be it, the business needs to pay double the price to the seller. The unnecessary inventory costs lie in the disrupted production, which leads to several other cost overheads.

These include overtime working of laborers, which may spark outrage, missed customer orders that will eat away at reputation and trust, and unplanned downtime. All these form the bigger picture of the problem, which was once just a missing spare part in the inventory.

And the greater fact is that this happens several times, without maintenance teams realizing the bigger impact of this. Hence, the losses will cost you thousands, even millions of dollars in gigantic setups.

Using a spare part management system always keeps things on track and never lets you miss any part.

If this happens in the case of main drive motors in production areas, the entire operation comes to a halt. This triggers great losses for industrial setups across sectors, which are hard to get covered.

Embracing preventive maintenance can minimize these risks, control costs and reduce downtime. Managing spare parts inventory efficiently goes hand-in-hand with preventive maintenance and inventory counts. Though it is not possible to completely eliminate reactive maintenance, preventive maintenance can be the approach for the majority of your maintenance tasks.

Wrapping Up

Choosing the right parts inventory management system brings real transformation. Many organizations offer a custom dashboard that gives a clear view of all aspects. Spare parts inventory management is a crucial thing for any business, and especially for the automotive industry; this is a huge game-changer. As we discussed, inefficiency can cause expensive overheads and also downgrade the company’s reputation. Hence, it is always better to work the smarter way with CMMS or EAM software, automated spare parts inventory software, and eliminate manual approaches.

Frequently Asked Questions

Spare parts inventory management is the process of organizing, tracking and controlling the supply of spare parts to ensure they are available when needed, while minimizing excess stock and reducing costs.

Effective spare parts management reduces unplanned downtime, improves operational efficiency, lowers carrying costs and ensures critical parts are available for maintenance tasks.

A CMMS helps automate tracking of spare parts, set reorder points, maintain bills of materials (BOM), streamline central inventory tracking and prevent stockouts or overstock situations.

Best practices include systematic identification of parts, managing unused parts, maintaining accurate BOMs, centralized inventory control, regular audits and using inventory software.

Inventory should be audited routinely based on usage frequency and business needs, commonly monthly or quarterly, to ensure records match physical stock and reduce discrepancies.