How Digital Transformation Extends Manufacturing Asset Lifespan: The Road to Resilience

Digital transformation is changing how manufacturing units operate. With the integration of technologies such as IoT, artificial intelligence, and predictive analytics, plant owners and managers can now monitor their assets in real-time and analyze overall equipment effectiveness with ease. This proactive, digital strategy-driven approach does more than only minimize downtime – it also extends the lifespan of valuable assets, ultimately leading to significant cost savings and enhanced productivity.

Let us explore the full spectrum of digital transformation in manufacturing, with special emphasis on extended asset lifespan making way for a resilient future of the industry.

Digital Transformation in Manufacturing Industry

The profound transformation of manufacturing is majorly driven by digital technologies. Encompassing the integration of digital tools across all aspects of the manufacturing, this leads to improved efficiency and better product quality.

Manufacturers, however, must navigate potential business disruptions during the transition that impact operations and the stability of the supply chain. Change management strategies and effective training could ensure a smooth transition process.

Additionally, the US National Institute of Standards and Technology (NIST) has come up with a framework that aids manufacturers with adapting to digital transformation effectively. The framework provides guidelines for integrating advanced technologies, fortifying cybersecurity measures, and improving interoperability across systems.

Manufacturing Digitalization: Automation & Beyond

The digital transformation journey is now imperative for manufacturing companies to gain a competitive edge. Technology, now extending beyond traditional automation, entails supply chain management, production, and maintenance.

A vital component of this digital transformation lies in data processing closer to the source through edge computing. It enables real-time visibility into operations and predictive analytics on a whole other plane. For example, by implementing digital manufacturing processes, General Motors ended up reducing downtime by 20%.

Industrial Digital Transformation: Unified Operations & Management

Industrial digital transformation brings everything together, connecting operations with management using integrated platforms such as Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Product Lifecycle Management (PLM). These systems can communicate in real-time and offer smooth workflows, consistent processes, and swifter response times.

Key stakeholders can gain insights into the entire operation with a single dashboard. It connects plant managers, engineers, and executives under a centralized system using smart manufacturing platforms.

Smart devices are a part of new-age digital transformation solutions. They offer training support and extended troubleshooting capabilities using a range of advanced features such as AI technology, virtual reality, augmented reality, and more.

Digital Strategy for Manufacturing Industry

Implementing digital transformation initiatives such as IoT for the manufacturing industry requires an extensive digital strategy that includes data collection, analysis, and actionable insights. This strategy needs to align with the organization’s goals, focusing on bringing added business value through improved equipment reliability and reduced maintenance costs.

According to BCG, manufacturing companies with a clear vision of digital transformation strategies are 70% more likely to achieve their desired business outcomes.

Key Benefits of Digital Transformation in Manufacturing: From Cost to Competitive Edge

Digital solutions for manufacturing are transforming the industry and delivering measurable results across operations. A Deloitte study states that manufacturing companies that opt for a digital transformation experience a marked rise of 23% in profitability and 19% greater efficiency when compared to those that do not.

The key advantages of implementing digital technologies are as follows:

Cost Savings

- The proactive approach of predictive maintenance minimizes unexpected equipment failures and breakdowns, resulting in significant cost savings.

- Identifying inefficiencies and optimizing workflows leads to reducing resource consumption and overhead expenses for the manufacturing environment.

Improved Product Quality

- Continuous monitoring allows manufacturing companies to detect and correct deviations in real time, ensuring compliance with quality control for manufactured products.

- Implementation of Digital Twin enables stringent quality checks, minimizing defects, and maintaining high standards.

Enhanced Operations

- Integrating automation and IT, digital technologies make way for streamlined workflow that bring down engineering costs and simplify processes.

- Implementing energy management systems contribute toward cutting energy costs and have a direct effect on reduced environmental impact.

Greater Customer Satisfaction

- Increased digital capabilities lead to quicker order fulfillment. In addition to that, enhanced production capabilities result in timely delivery of products to customers.

- Moreover, enhanced process efficiency and real-time data analytics make way for accurate order execution that work toward gaining higher customer trust and loyalty.

Overcoming Challenges in Digital Transformation in Manufacturing

Despite a plethora of benefits, digital transformation also comes with challenges such as high upfront costs for implementation, threats of cybersecurity being tampered with, and resistance from the workforce at the outset.

Overcoming these challenges becomes fairly easy when manufacturers:

- Approach the digital transformation process in phases, and not all at once.

- Ensure that C-suite is onboard and there is cross-departmental support.

- Offer comprehensive training to the workforce.

How to Implement Digital Transformation in a Manufacturing Plant

Digital transformation efforts in manufacturing companies requires a structured, systematic approach:

- Assessment: Evaluate current processes, existing infrastructure, and status of digital integration.

- Setting goals: Establish clear and measurable goals that are aligned with business needs.

- Selecting technology: Choose scalable and interoperable digital solutions that work to reduce costs.

- Pilot projects: Begin with small steps in a controlled environment, leveraging digital transformation capacities gradually.

- Data integration: Ensure all relevant data is integrated and a seamless flow is established to bring manufacturing digital transformation into place.

- Training: Provide opportunities to the workforce for upskilling themselves to adapt to the new digital tools.

- Scaling up: Expand gradually based on the success rate of the pilot project and feedback.

The Ford assembly unit based in Chicago followed a similar model, beginning with predictive maintenance pilot projects leading to full-scale deployment which increased machine uptime by 15%.

Digital Transformation for Regulatory Compliance in Manufacturing

The digital transformation in manufacturing process also simplifies regulatory compliance with software solutions that help to reduce costs while offering key benefits. New-age technology vendors provide automated documentation, real-time monitoring, and digital audits that ensure adherence to various industry standards such as FDA, ISO, and OSHA.

In the food manufacturing sector, Nestle uses automated compliance reporting systems to meet the strict health and safety regulations in all its manufacturing units.

Smart Factory Digital Transformation: Building Intelligence & More

Smart factories are at the peak of smart manufacturing. These advanced facilities depend on an interconnected system of IoT devices and machine learning to create agile and data-driven production environments. The systems are also capable of tracking energy consumption, contributing to operational efficiency along with sustainability in the manufacturing process.

A Siemens plant in Germany is a stellar example of a smart manufacturing firm. It relies on 75% automation for its production process, leading to a remarkable quality rate of 99.99885%.

Digital Transformation in Smart Manufacturing: Key Technologies

In the era of smart manufacturing, integrating the Internet of Things (IoT) has become crucial. It ensures enhanced asset longevity and increased operational efficiency. From embedding sensors into machinery to getting real-time insights delivered to interactive dashboards, manufacturers can stay updated on equipment performance that enables them to detect equipment faults early while reducing unplanned downtime.

Integrating IoT for Predictive Maintenance in Manufacturing

With continuous monitoring and analysis of equipment health, traditional industrial processes make way for IoT-enabled predictive maintenance.

The benefits of IoT for predictive maintenance are numerous, with some of them detailed as follows:

- Managing complex processes efficiently with precise coordination and control. By swiftly identifying and resolving potential issues, operations can run smoothly while maintaining high quality standards.

- Driving business growth by reducing downtime and maintenance costs drastically. The improved operational efficiency levels lead to increased production capacity, adding a competitive advantage to companies in the manufacturing sector.

- Leveraging key technologies such as advanced sensors, data analytics, and machine learning algorithms enable manufacturing companies to stay updated while aiming to reduce costs. From production costs to overheads, advanced manufacturing technology provides actionable insights across the board.

- Additive manufacturing processes, such as 3D printing, ensures reliability and precision in equipment, streamlining the manufacturing process. Continuous monitoring of components leads to reduced material waste and improved product quality.

- Within the competitive landscape of the industry, manufacturing leaders who adopt IoT-enabled processes for predictive maintenance are putting their organizations at the forefront of innovation. In the aerospace industry, for example, this means ensuring the reliability and safety of aircraft components.

- Reducing unexpected equipment failures, predictive maintenance refurbishes existing infrastructure by predicting issues that could cause supply chain disruptions. Offering all-around supply chain optimization, IoT makes way for greater cost savings as well.

- Finally, integrating IoT for predictive maintenance drives enhanced business value for manufacturing businesses. Successful digital transformation in manufacturing leads to reduced production costs and improved efficiency with optimal utilization of resources.

Implementing Smart Sensors in Manufacturing Equipment: Refined Precision Monitoring

Driving increased precision and reliability in manufacturing, smart sensors provide real-time insights into operational conditions of manufacturing equipment.

Pressure Sensors

These capture pressure fluctuations and convert them into electric signals. They identify force in liquids and gases and offer control signals to display devices and are often used in hydraulic systems to check fluid pressure levels.

Temperature Sensors

These collect information on temperature and convert it into specific values. They contain digital temperature sampling cards and are widely used in industrial automation, especially food, metal, and chemical manufacturing industries.

Proximity Sensors

These have the capability of sensing the presence of an object. Using techniques such as the change in an induced magnetic field, these recognize the proximity of the target object and provide output to the corresponding switch signal. They are used mostly to enhance safety and automate assembly lines during the manufacturing process.

Force Sensors

These detect forces such as compressive or tensile force and translate them into electric signals that directly reflect the degree of the force. Used widely in the robotics industry, these send signals to controllers, indicators, and computers.

Infrared Sensors

These use infrared wavelength signals to create and compile data without any direct contact to the target object at the time of measurement. Since there is no physical contact or friction between the target object and sensor, these are extremely sensitive and usually have super-fast response times.

Flow Sensors

These sense the movement of liquids, gases, and solids that flow through a pipe or conduit. Widely used in processing industries, they aid in optimal performance of machines. Flow sensors are of electronic, ultrasonic, or partially mechanical types.

Motion Sensors

These detect objects that move or change positions on the factory floor. They can sense the positions of valves, throttles, doors, and more and have location-tracking abilities that aid in identifying precise positioning of machines, tools, and relevant items within the manufacturing facility.

Smoke Sensors

These identify smoke or airborne particulate and gases and are expressly required in an explosive or flammable manufacturing environment. Using their embedded MCU control, these sensors send signals to sound the alarm on detecting the presence of fire-originated smoke.

Optical Sensors

These operate mostly on zero interference, non-contact measurement metrics with high-speed transmissions and remote-control features. They detect visible or infrared light forms using laser interferometers, encoders, gratings, and fibre optics, optimizing positioning in high-speed production lines.

Image Sensors

These sensors are categorized into two: charge-coupled devices (CCD) and complementary metal-oxide-semiconductor (CMOS). They convert optical images into electric signals and are used in analog and digital imaging devices such as computer visions, camera modules, medical imaging tools, thermal imaging devices, sonar, digital cameras, night vision tools, and the like.

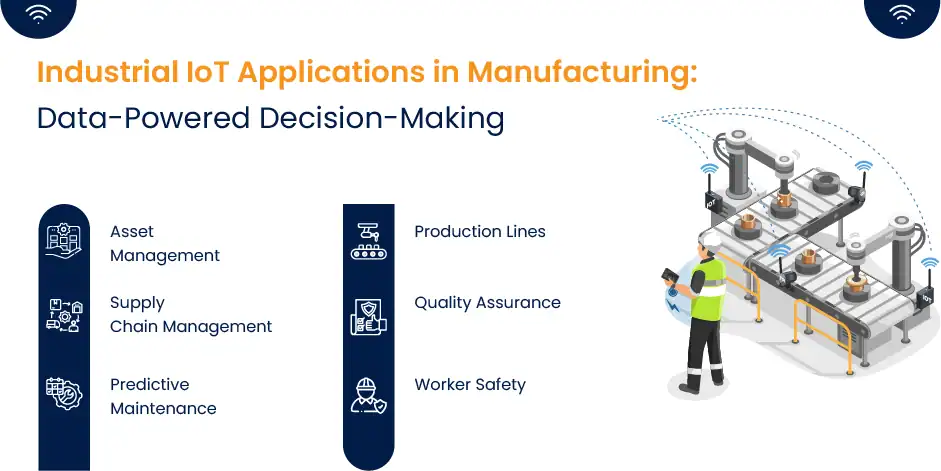

Industrial IoT Applications in Manufacturing: Data-Powered Decision-Making

From workplace safety to operational transparency, the Industrial Internet of things (IIoT) offers a plethora of advantages. 3M, for instance, has integrated RFID tagging, smart sensors, and real-time data analytics, completely transforming its traditional safety protocols to meet the digitization needs of the hour.

Asset Management

Industrial IoT systems track the condition and location of assets that help manufacturers optimize usage, manage equipment effectiveness, and schedule proactive maintenance.

Supply Chain Management

GPS and RFID tracking systems offer detailed real-time visibility into shipping and inventory systems that positively impact stock management systems and delivery timelines by reducing bottlenecks.

Predictive Maintenance

Sensors can monitor key machine health indicators such as vibration and temperature to predict potential failures and schedule maintenance of the same before breakdowns occur that go on to extend asset life in the long run.

Production Lines

Industrial IoT sensors and industrial robots automatically adjust production parameters, reducing human errors and increasing speed and precision that optimizes throughput.

Quality Assurance

Data from sensors offer the information necessary to check products for quality standards so flagged issues can be adjusted immediately to address inconsistencies or defects.

Worker Safety

Sensors fitted into wearable devices monitor workers’ health metrics and working conditions, providing timely alerts for potential health risks or safety hazards, ensuring compliance with labor codes.

Real-Time Data Monitoring in Factories: Drastically Reducing Downtime

A cornerstone in the modern industry landscape, real-time data monitoring enables manufacturing companies to reduce downtime while improving product quality. Toyota’s plant in Kentucky, for instance, has successfully reduced downtime by 28% after implementing real-time monitoring systems.

Production Monitoring

Real-time dashboards aid in tracking production output and quickly identify bottlenecks. At Siemens, the integration of real-time monitoring of their manufacturing production process includes employing IoT sensors and advanced analytics. Reports show a significant reduction in their machine downtime, enabling them to achieve greater operational efficiency and product quality.

Condition Monitoring

Regularized assessment of machine health is imperative when it comes to preventing unexpected manufacturing equipment failure. BASF, a renowned chemical company, uses remote condition monitoring systems for its plant in Beaumont, Texas. Analyzing data on the health of 63 prime assets, they can now promptly identify anomalies and prevent catastrophic failures.

Quality Control

Early detection of defects ensures maintenance of product quality standards. This, in turn, makes sure the manufacturing value chain remains uninterrupted with fewer quality issues. General Motors, for instance, has adopted real-time quality control monitoring in its assembly plants – making use of an intricate network of sensors and data analytics tools, leading to a marked decline in the number of defects per vehicle produced.

Downtime Tracking

In order to ensure the prevention of future breakdowns, it is crucial to understand and analyze the root cause of downtime. For example, Carolina Precision Manufacturing sought help from data analytics to manage productivity on the factory floor. A real-time monitoring model now helps them eliminate material waste and reduce downtime.

Predictive Maintenance

Equipment lifespan extends greatly when maintenance scheduling follows actual wear and tear data. General Motors uses IIoT to predict maintenance requirements across all its manufacturing plants, decreasing downtime by 15%. They have managed to save millions in maintenance costs so far and have improved overall production efficiency.

Workforce Management

Monitoring worker efficiency and automating labor planning not only improves efficiency among the workforce but also ensures fewer workplace injuries. Artificial intelligence is a game-changer for this format of preventive maintenance strategy by escalating defects and addressing machine issues to support human workers. Resultantly, sensor data equipped with artificial intelligence is mitigating manufacturing labor shortage issues.

Digital Twin Technology in Manufacturing: The New Dawn

Extending aftermarket services, Digital Twin has emerged as a much sought-after technological solution for industries worldwide. Reports say that Rolls-Royce uses Digital Twin for jet engine maintenance and has been successful in reducing maintenance costs by 30% while extending maintenance intervals by up to 50%.

With the virtual replica of physical assets, processes, and systems with Digital Twin, the manufacturing industry has gained renewed perspective into real-time simulation, diagnostics, and predictive analytics – all precursors to data-driven decisions along the way.

Here is a look at what some of the manufacturing industry leaders implementing Digital Twin in their production process and capabilities.

| Company | Area of Digital Twin Application | Results |

| General Electric | Jet engine performance monitoring | Increased engine uptime; reduced reactive maintenance by 40% |

| BMW | Vehicle manufacturing | Reduced production errors; improved manufacturing quality |

| Maserati | Car development process | Reduced operational costs and time; decreased time to market by 16 months |

| Unilever | Production optimization | Reduced product launch time by 50%; cut capital expenditures by 70% |

| Ferrero | High-bay warehouse commissioning | Brought down commissioning time by 30%; achieved target availability 88% quicker |

| Kaeser | Compressor manufacturing | Could remotely detect potential faults; prolonged product life and reduced maintenance costs |

The integration of Digital Twin in the manufacturing process is more than just a trend – it is a marked shift towards increasingly connected systems and smarter, more resilient, and more efficient operations.

Industry 4.0 Manufacturing Solutions: The Future Is Now

Industry 4.0 is bringing together IoT, AI, robotics, and cloud computing into a powerful, robust ecosystem. From boosting productivity to slashing inventory levels, these smart, connected systems are heralding a new dawn in manufacturing. More than speed or efficiency, this digital transformation is more about extending the lifespan and performance of every asset on the manufacturing shop floor. For plant owners and managers, riding the digital wave is hardly a choice anymore – it is the way forward. Those who invest in intelligent technologies like InnoMaint today are setting up their operations for greater success and assets for a longer lifespan, paving the way for greater returns and a smarter, resilient position in their respective domains.

Frequently Asked Questions about CMMS

Digital transformation in manufacturing refers to the integration of digital technologies—like IoT, AI, cloud computing, and data analytics—into all areas of the manufacturing process. This shift improves operational efficiency, reduces downtime, and enhances decision-making across production, maintenance, and supply chain management.

Digital transformation extends asset lifespan by enabling predictive maintenance, real-time monitoring, and smart alerts. With technologies like IoT sensors and digital twins, manufacturers can detect potential failures early, optimize maintenance schedules, and reduce wear and tear—leading to longer equipment life and fewer breakdowns.

Predictive maintenance helps manufacturers avoid costly equipment failures by forecasting issues before they happen. Benefits include reduced downtime, lower maintenance costs, improved asset reliability, extended equipment life, and enhanced safety compliance.

Industry 4.0 maintenance solutions include IoT sensors, AI-based analytics, smart wearables, edge computing, digital twins, and real-time dashboards. These technologies provide visibility into asset health, enable remote diagnostics, and support data-driven decision-making for better maintenance planning.

Yes. Smart sensors monitor real-time metrics like temperature, pressure, and vibration. When anomalies are detected, alerts are triggered so preventive action can be taken. This significantly reduces unplanned downtime and maintenance costs.

Digital twins create a virtual replica of physical assets, allowing manufacturers to simulate performance, diagnose issues, and predict maintenance needs. This approach improves asset planning, reduces failures, and enhances overall equipment effectiveness (OEE).

Start by assessing your current systems and defining goals. Pilot small projects with scalable technologies like CMMS or IoT-based monitoring. Train your workforce, integrate data sources, and gradually scale based on feedback and results.

Studies show manufacturers that adopt digital maintenance strategies experience up to 20-30% reduction in maintenance costs, 15-40% increase in asset uptime, and a significant improvement in safety and compliance.