The Complete Guide to CMMS Software in 2026: Selection, Implementation & Optimization

You will often hear industry people say that around 70% of CMMS (Computerized Maintenance Management System) implementations collapse in practice.

Gregory Perry, Senior Capacity Assurance Consultant, Fluke Reliability, in his white paper publication, mentions the same.

Now failure has a different face here; it does not mean that the CMMS crashes, the project is cancelled, or the system is removed from operation.

At the core, the issues are different, and most firms aspiring to use CMMS or have already implemented it are unaware of them.

From the point of view of non-maintenance stakeholders in a firm, the system is live and in operation. However, the CMMS system operates irrelevantly, barely fulfilling the gaps for which it was implemented initially.

The system is not driven in the accurate direction; instead, it is just running, creating a fake sense of computerized management.

Buying and implementing a CMMS software does not fix the issues; instead, it exposes those.

What is a CMMS?

CMMS, or a Computerized Maintenance Management Software/System, is a complete framework to manage organizational assets, reduce downtime, increase operational efficiency, and much more.

It is a software or platform (different from Enterprise Resource Planning software) acting as a bridge between facility managers, the assets, facilities, or equipment, and the technicians.

Creating a cohesive system ensures consistent data exchange, accountability, and structure in the daily maintenance operations of firms across industries.

How does a CMMS work?

The capabilities of a CMMS software are assigned to various modules within it. Every module is connected to the other, working as a single system and supporting the tasks of other modules. Let’s go for a brief rundown of the fundamental modules present in every good CMMS:

Work Order Management

This module creates an environment for facility managers to create, assign, and track maintenance tasks.

Advanced versions of this module also support tracking of the technician’s location in real time. However, its capabilities go beyond simple task tracking, where it creates a structured workflow.

It further ensures that the workforce is not exploited by prioritizing tasks, assigning them based on skill and workload. Through this, the platform/system helps avoid resource clashes and is beneficial during peak hours, when operational consistency is critical.

Asset Registry

The asset registry module creates the foundational data on which the maintenance intelligence runs to improve asset reliability.

However, this foundation data is not disorganized; instead, it is structured and consolidated data that includes asset metadata, maintenance history, warranties, manuals, and performance data (with detailed graphs for analysis). This data also helps in asset lifecycle management systems for physical assets.

The asset data registry helps the CMMS system offer actionable insights to facility managers for informed decision-making across maintenance, operations, finance, and capital.

Condition Monitoring

This part of a CMMS platform lets you shift from traditional time-based maintenance to condition-based maintenance.

The features require IoT sensors that send live data from the assets to the system. The data includes detailed metrics about the current temperature, pressure, and other essential states that determine asset health.

Analyzing that data allows teams to understand underlying failure causes, detect anomalies early (Preventive Maintenance), and solve issues before they escalate into major ones.

Predictive maintenance

Modern CMMS platforms come with this advanced module that runs on Artificial Intelligence (AI) and Machine learning (ML) algorithms.

A 2024 State of Industrial Maintenance Report indicates that approximately 30% of the facilities use predictive maintenance.

PdM, or Predictive maintenance software, is growing, but it is still not widely adopted. Several organizations still use a run-to-failure approach, and some preventive maintenance. But if we see on a global level, only a minority of companies have integrated predictive maintenance.

Reports and Analytics

If you have all the operational data along with the maintenance data structured in a system, it becomes a great source for analysis and reporting.

Both the data sets can be tallied, which helps in identifying operational issues that can be complemented by restructuring particular maintenance tasks. This gives a firm control over both the primary aspects, which are: maintenance and operations.

And this happens based on defined KPIs or Key Performance Indicators, such as MTBF.

(Mean Time Between Failures), MTTR (Mean Time To Repair), downtime, and expense trends. This data on a dashboard dissected by intelligent AI and ML algorithms makes today’s maintenance smart, secure, and highly cost-effective.

Mobile Maintenance

Maintenance occurs at the site, and not in a room. Machines, equipment, surface issues, or undergo breakdowns where the groundwork happens.

And technicians rely on that, which means there is a gap between the system and the field. Today’s CMMS platforms bring mobile access to technicians in the field.

They can access asset information with a simple barcode scan, update work status, send a notification for additional assistance, capture photos, and send to managers all within their mobile devices. Every action is part of a structured workflow and remains in a single place, which can be tracked afterwards. This will improve communication among technicians and facility managers, ensuring task accuracy.

When technicians perform these actions, they are creating structured operational data, which becomes the foundation for acquiring more advanced capabilities.

However, here is where most organizations fail, as

“they talk about the importance of AI-integrated CMMS, but do not address the fact that it needs structured and consistent data to deliver accurate predictive and automation insights.”

This is what organizations need to understand before they go for a costly, unplanned CMMS implementation for proactive maintenance.

So, this guide is for operational leaders, maintenance managers, and other roles who are responsible for results and not just reports.

The guide will teach you how to “not digitize” your facility maintenance chaos further and instead perform a meaningful CMMS implementation.

Let’s see how to select, implement, and optimize CMMS software for 2026 and beyond.

But before that, let’s understand why CMMS software is no longer a work-order system; instead, it is now a Decision Engine.

CMMS in 2026: What Has Changed

Out on the internet, most CMMS-related content talks about digitizing work orders, logging failures, tracking labor, and generating compliance reports.

It reads like it is stuck in 2015, while the value of CMMS systems has shifted drastically in 2026.

The old model CMMS answered, “What has happened?”

Modern CMMS adds value by answering, “What should be done next and why?”

If your system in 2026 only manages work orders, it is operationally irrelevant.

Today’s systems not just store and display maintenance history, but interpret that data, and answer the following questions:

Why did those failures happen?

Are Preventive Maintenance schedules under-maintaining assets?

What patterns need to be fixed in order to reduce downtime?

Without analysis of the maintenance data, everything is noise.

In 2026, CMMS software is an intelligent layer controlling maintenance and not just recording data.

It now leverages that data to come up with actionable operational insights, helping facility managers make sound decisions. An Enterprise Asset Management (EAM) cannot deliver the outcomes that a CMMS would deliver.

This changes the early origin nature of CMMS, making it a decision engine from a clerical or digital logbook tool.

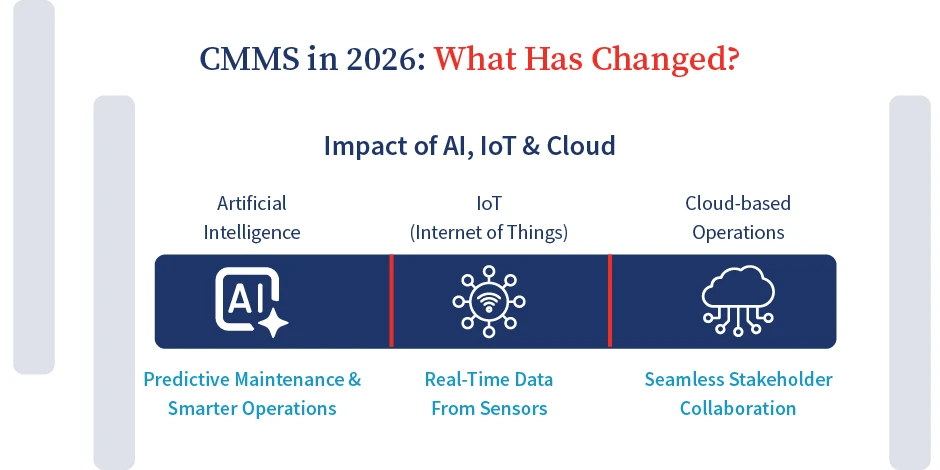

Impact of AI, IoT & Cloud一

Artificial Intelligence

Industry people expected AI (Artificial Intelligence) to predict failures once integrated with CMMS systems.

But in reality, maintenance data quality deficits keep stalling AI readiness from the core.

In 2026, it is more sobering than promising; not because AI integration was unsuccessful, but because AI itself faced difficulties in operation.

Artificial Intelligence revealed that most organizations do not have their maintenance data structured.

There are inconsistencies in failure codes, vague work order descriptions, and empty root cause fields.

While humans can work with this type of data with experience and intuition, AI would not be able to do that.

The uncomfortable truth for most organizations is that AI exposes weak and undisciplined maintenance operations.

IoT (Internet of Things)

Talking about IoT, its integration added to the data volume from assets. Maintenance systems receive real-time data from sensors, but without the capacity to contextualize that.

Organizations need to understand that data volume will not enhance decision capability, but data clarity will.

IoT solutions provided continuous condition data, surfacing failure signals earlier; however, no clue for organizations on when to act, who is responsible for risky decisions, and how different maintenance tasks should be prioritized.

Cloud-based Operations

Cloud technology also has a profound impact on IoT, as it makes cloud based CMMS more readily deployable, but we will explore what it has not fixed.

It made integrations easier and installed updates faster, with more seamless stakeholder collaboration. However, it did not fix things like poor maintenance workflows, bad data discipline, and a lack of accountability.

These aspects require foundational work, which many organizations step back from.

Having a system ready to embrace the perks of a CMMS software is critical.

Before you even talk to vendors, frame a strategy to fix gaps in your maintenance operations so they do not backfire.

As per a recent survey by another recognized CMMS platform, like Innomaint, 70% of CMMS projects fail to launch.

You have already locked in failure by investing in CMMS without a plan!

Firms cannot resist the temptation to jump right into deploying the first-appealing CMMS they find.

This is where they make an irreversible mistake, which guarantees disappointment rather than a successful CMMS in operation.

This is what no CMMS vendor wants you to read一

Failed maintenance software implementations do not arise from bad software or non-dedicated facility managers.

Vendors do not want to air these, as it will reveal that most firms lack the foundational readiness to buy and deploy a CMMS solution.

The Readiness Checklist:

Maintenance Maturity

Before implementing a CMMS solution, your maintenance practices should be mature enough to be system-driven.

If most of the tasks are still reactive maintenance instead of planned, or technicians follow a traditional job, CMMS will suck.

Organizations should have an operational, basic preventive maintenance intelligence spearheaded by humans.

If a firm has it, it reveals that there is structured data logging from equipment, which is further analyzed to identify patterns, and scheduled maintenance is planned accordingly and reduce inventory costs.

If all this is done manually beforehand, little tweaks here and there would make the CMMS implementation seamless. Once operational, organizations can yield their full potential and witness their maintenance transforming from manual to automated.

Data Hygiene

If an organization actively maintains logs, tracks failure and maintenance history, with detailed data, it is a huge plus with little concern for data garbage. It is also a great data source for detailed asset tracking.

Garbage data grows faster than good data, and CMMS implementation multiplies the already available data.

Hoping CMMS will fix,

Duplicated asset names,

Missing manufacturer or machine model info,

Or, inconsistent failure codes are false optimism.

Data hygiene matters as AI and ML-based analytics depend on consistent and structured data.

Organizations need to establish new data protocols, fix current ones, and make maintenance data operationally meaningful.

What is the minimum readiness threshold?

An organization that can confidently answer the number of assets maintained, their position, and can judge what good and failed maintenance looks like for their setup.

Clarity in Asset Prioritization

Most organizations casualize the criticality of assets and asset history.

If every machine and equipment is critical, then nothing is prioritized in reality, and there will be no positive impact on equipment lifespan.

They will not find measurable results even after their CMMS software is fed with good, structured data.

However, asking these questions before the implementation will simplify execution:

- Do our assets have a documented ranking system based on risk?

- Can we clearly distinguish between failures that stop production vs. those that delay?

- Are safety and compliance measures defined for the CMMS?

For instance, before choosing your CMMS solution, you must have sought out which inspections should not be missed, which incidents should be reduced, and most importantly, which regulations apply.

Along with this come the people who will be adapting the new CMMS workflow, leaving behind their existing work traditions.

Workforce Capability

Even after structuring data, defining sharing protocols, and prioritizing assets, a big void of ambiguity still remains.

The people who are expected to use the CMMS are expected to adapt; organizations do not address whether the existing workforce is ready to adapt to the new technique.

While this is a pressing concern, something else is even more critical.

It is not only about the willingness to adapt, but your maintenance personnel should have behavioral readiness, skill alignment, and accountability clarity.

CMMS forces organizations to maintain a structure, which clarifies who owns what.

It eliminates operations on unofficial authority; for example, before CMMS, the senior technician would decide the tasks, and the planner created the maintenance requests and even approved them.

Powerful maintenance management software like Innomaint forces realignment of your maintenance practices and roles.

Messed-up operational structure undermines CMMS implementation success, even if there is premium software, a good budget, and vendor support.

Below are some red flags that, if present in your system, there is no point in moving forward now with the deployment.

Red Flags That Guarantee CMMS Implementation Failure

Most of these are not risks, but gaps that slowly derail your CMMS from providing measurable outcomes.

Deciding to clean data after going live

The single area that is overlooked is the primary reason for failure.

Several organizations do not have a documented asset list, locations are inconsistent, and failure codes are undefined. With this data, a CMMS would never work the way intended; instead, it would burn capital and demotivate owners, further increasing the chaos that they intended to alleviate with a CMMS.

Selecting the solution before process definition

If the workflow of an organization is not structured, CMMS implementation is destined to fail there.

These solutions demand defined hierarchies and departmental structure, which, if not there, will shatter the whole system.

Most firms think that CMMS can be managed by the IT team, which is a big red flag. This is because the team is not trained to follow maintenance workflows.

Unlike dedicated maintenance teams, that team will measure success by “system live”, rather than by the number of work orders executed and maintenance data consistency.

Implementing CMMS without a goal

Implementing a CMMS with the notion that ‘we need a CMMS’ is not going to work in 2026.

Modern CMMS platforms now offer advanced maintenance strategies, with their features being more targeted to particular tasks. This is done for better outcomes by the integration of cloud, artificial intelligence, machine learning, and IoT.

So, today it is not just a software that you will be using, it is a complete system, which consists of high-ROI capabilities that are guaranteed to be wasted if your goal is unclear.

The best way is to audit your current state to identify breakdown patterns, data gaps, compliance risks, and other process inefficiencies that could be addressed with a CMMS implementation.

But once you have defined the goals, this question follows immediately:

How Can We Implement the CMMS Now?

A publication published by an expert from Noria Corporation revealed that 80% of CMMS implementations fail. What organizations need to understand is that the process is not a software rollout; instead, it is a controlled operational transition.

Your implementation will roll out in phases rather than all at once. So let’s start with:

Assigning Clear Ownerships

Before the technical steps required for the CMMS Software to get running, such as configuration, training, or data entry, you need to decide on the roles and responsibilities.

Forget about the CMMS benefits; if the ownership is messy, the implementation will itself stall.

For instance, a clear structure would be:

- Executive sponsors take the role of removing obstacles and enforcing the adoption from various aspects.

- The Maintenance owner has full control over the workflows, regulatory compliance, and intended outcomes.

- CMMS Administrator focused on system configurators and overall governance.

Define the Problems the CMMS Would Solve

The thing most organizations do wrong is to look at the CMMS maintenance software features. They fantasize over those and ignore whether they have a practical implementation or not.

The right step is to identify the problems and then look for a solution that solves those. With this approach, the true solution will surface, instead of you being the victim of persuasion by CMMS vendors.

Before choosing a solution, firms should be clear about:

Which reasons are causing the maximum downtime?

Which assets cause repeated failures?

In which areas is the maintenance work still reactive?

Prepare the Minimum Viable Data

We discussed this in an earlier point, where we learned that cleaning the data after going live is pointless.

However, trying to clean years of maintenance data inconsistencies will delay the implementation endlessly.

Here, the strategic way is to aim at organizing the critical data, which includes:

- Important assets for operation

- Basic asset hierarchy

- Core preventive/ maintenance tasks

- Standard failure codes

If you aim for the perfect moment for implementation, that will not exist unless you start. Make the data usable, and then always look for improvement scopes to make the system truly aligned with maintenance operations with minimal disruption.

Standardize the workflows before CMMS Configuration

In case of a standardized workflow being missing, the CMMS will fail to operate on its full potential.

A documented, standard workflow ensures team alignment, communication, and quick execution of work orders for administrative tasks.

Before configuring your CMMS with an uncertain workflow, standardize and document the following things:

- Work request raising process

- Work orders approval process

- Work order prioritization

- Recording of completion

Since these processes are elemental to the platform’s functioning, establish these workflows firmly and then configure.

Go Pilot Before Wide Implementation

When the workflows are finally standardized, data is made usable, and goals are defined, now comes the step for implementation.

However, being over-enthusiastic can kill the process before it starts.

Hence, go for a phased implementation by choosing one plant, department, or asset group. When you run the system for 60-90 days, you can validate that:

- Workflows are working

- Fix data issues

- Adjust training based on workforce reaction

These factors will define the system’s stability, from which you can gradually scale it for the whole organization and achieve successful implementation.

Once the CMMS is operational, a post-decision doubt comes as a nightmare for the owners. They become uncertain of whether it will work or not, and give the calculated ROI.

Simply put, an optimized CMMS provides good Return on Investment.

ROI Calculator: Core Task in CMMS Implementation

Organizations aim for maintenance improvements while implementing a CMMS. But they are focused on transferring those into numbers, which could actually define business improvement.

This should be done at the stage where you have chosen the optimal CMMS platform. Right after that, the next step is to quantify the “why” before buying. A genuine ROI calculator will help you create a baseline for accountability.

It helps team maintenance managers capture metrics, tally them with the expected value, and define what success will be measured against.

When calculating ROI, always go for one that works on maximizing the labor resources, has automated report generation, cuts production costs, and more.

Several organizations think that Enterprise Asset Management (EAM) can serve the purpose of a CMMS. But here’s where they differ:

Comparison Between CMMS & EAM

| Aspect | CMMS | EAM |

| Core Purpose | Execute and control the maintenance activities, along with asset management | Manages assets for their entire lifecycle |

| Primary focus | Maintenance operations | Asset strategy and maintenance |

| Asset Criticality | Maintenance focused | Focused on an asset’s impact on the business |

| Reporting Agenda | Operational efficiency | Strategizes only over asset performance |

| Cost | Lower | Higher |

Get this e-book right now for free if you want to explore the capabilities of an EAM further.

Optimizing Your CMMS Platform

When your implementation is stabilized, the optimization can begin. It means increasing planned, high-value maintenance and reducing the avoidable failures.

So it starts with,

Stabilize the Foundation First

Before starting the optimization process, organizations need to stabilize their existing systems.

Here are things that you need to ensure:

- The CMMS data should be the single source of truth

- Work order statuses are up to date

- Preventive maintenance is reliably tracked

- Asset hierarchy is defined

Shifting from Reactive to Planned

Most of the organizations have their maintenance activities reactive. It means that once the problem has arisen, only then are the maintenance tasks conducted.

Even if preventive maintenance (PM) has been adopted, the schedules often fail to deliver measurable outcomes, reducing maintenance costs.

The target of facility managers should be to make 70% of the work planned and 30% of the work reactive to make it their best CMMS software implementation.

The CMMS platform will do the tedious work of analyzing reactive failure patterns, suggest PM schedules to reduce repeated failures, and eliminate tasks that do not prevent failure.

Improve Work Order Quality

If your work order quality is poor, the data generated and recorded will be useless for the maintenance professional.

The outcomes will be inaccurate, and slowly, the workforce will try to disregard the implementation, which leads to the failure of reliability centered maintenance.

If your work orders are vague, incomplete details are entered, and closed without enough details. To combat such practices, the maintenance processes should be disciplined, and so should the workers.

To improve the work order quality, there are some actions you need to perform:

- Standardizing failure and cause codes

- Proper completion notes

- Eliminate empty fields in work orders

Use KPIs for Improvement and Not Just Reporting

Most organizations think the Key Performance Indicators are to be used for detailed reporting.

Yes, that is true; however, if that detailed report does not satisfy the ROI, then there is no use for it. But the real effectiveness of analyzing the KPIs comes when you review them weekly or monthly, based on the requirement for advanced analytics.

Since these indicators are owned by specific roles, you can easily identify the team creating conflict, from where you can resolve the situation. These KPIs are also helpful to analyze maintenance costs.

Here are the key KPIs you should measure:

- PM Compliance

- Planned vs Reactive Work Ratio

- MTBF and MTTR

- Work order backlog health

- Maintenance cost per asset

So, these were the four key ways you can optimize your CMMS workflow and operations to maximize the ROI and reduce costs.

Now, before we step back and summarize, let’s see the impacts of CMMS on a real project.

CMMS Implementation on a Real Project

Here is a case study of Innomaint CMMS, digitally streamlining maintenance of 200+ knitting machines and 700 IT assets for Bonjour.

With a rigorous production process, this top-tier socks manufacturer and exporter faced challenges in managing the large number of machines from a single point. They could not generate maintenance reports from remote locations and had to rely on floor staff for reports.

Additionally, their line supervisors faced resistance while assigning tasks to engineers per the machine arrangements.

Being an advanced CMMS solution, Innomaint offered them its built-in EAM solution. Aligning with our strategies, they saw

- a 20% increase in asset lifespan,

- a 15% increase in productivity,

- and achieved automation.

Read the full case study here to explore how we raised the standards of their maintenance program.

Final Thoughts

While CMMS (facility management software) can bring a paradigm shift in your maintenance operations, you need a proper plan before implementation and going live. The best way is to identify the mistakes that make most of the CMMS maintenance programs fail. Once you identify those, you can plan accordingly without touching those failure points and seamlessly move through the implementation, go-live, and optimization process.

Frequently Asked Questions

Small owners want to become global and stay relevant, for which they need to embrace the potential of modern technology. While for them, powerful software solutions are expensive, modern platforms offer the flexibility to purchase the required modules and not the complete software.

When work orders are assigned and completed for a particular asset, InnoMaint CMMS logs that under the specific asset history data. And this is possible because everything happens under a single system. So, whenever it is required, authorities can access that with the help of maintenance managers.

Most organizations treat their CMMS project as a software deployment. In contrast, it is the initiation of a complete system that works on disciplined maintenance actions and records.

Here are the key KPIs that matter the most:

Work Effectiveness

Schedule Compliance

Maintenance-to-Failure Control

Decision Latency

Data Discipline & Quality

Cost Control