AI and IoT for Sustainable Manufacturing: Smarter, Greener, and More Efficient Plants

As a matter of fact, the manufacturing industry witnesses stiff competition and is highly regulated. Such factors demand environmentally conscious operations and the adoption of sustainable practices while maintaining operational efficiency.

Sustainable manufacturing is no longer an option but a necessity in today’s competitive and regulated industrial landscape. By integrating AI and IoT in manufacturing, companies can achieve energy efficiency, predictive maintenance, and resource optimization, while also meeting compliance standards and reducing carbon emissions. From Asset Lifecycle Management (ALM) to work order automation, these technologies empower manufacturers to cut waste, extend equipment life, and streamline production. As smart automation systems and Industrial IoT continue to evolve, sustainable practices are becoming synonymous with operational excellence.

What is Sustainable Manufacturing with AI & IoT?

Sustainable manufacturing is the practice of producing goods in a way that minimizes environmental impact, conserves resources, and ensures long-term efficiency. It is not just about compliance with environmental regulations it is about building future-ready factories that are profitable, resilient, and eco-conscious.

The integration of AI (Artificial Intelligence) and IoT (Internet of Things) has accelerated this shift. IoT sensors embedded in equipment continuously track parameters like temperature, vibration, energy consumption, and air quality. This telemetry data is then processed by AI models, which can analyze massive volumes of information in real-time to uncover inefficiencies and recommend improvements. For example, AI can identify energy-hungry equipment and suggest optimized operating schedules, while IoT ensures accurate monitoring of actual consumption.

Smart automation systems also play a central role in sustainable manufacturing. By linking machines, robots, and human operators in a connected ecosystem, these systems make production lines more adaptive and efficient. In parallel, digital manufacturing approaches enable virtual simulations, predictive modeling, and digital twins, reducing waste during product design and testing phases.

At the core of these innovations lies resource management optimizing energy, water, raw materials, and human resources. Instead of reactive, manual processes, manufacturers are now able to embrace a proactive, data-driven model that balances production goals with sustainability targets. This is why AI and IoT are increasingly viewed as the cornerstones of modern, sustainable plant operations.

Understanding Sustainability in Manufacturing

Manufacturing facilities management has evolved significantly in recent years. It is no longer a behind-the-scenes role but a strategic function driving sustainability, technology integration, and workforce adaptability.

Sustainability denotes varied meanings across industries. In a general context, it commonly refers to creating energy-efficient software. In a manufacturing setting, it is about optimizing asset performance, efficient resource management, and minimizing waste.

Questions like

1.”Is the resource utilization of the equipment reasonable?”

2.”Is an aging piece of equipment really an asset or more of a liability?” is key to keeping the ball rolling(productivity) and the sustainability equation balanced.

Manufacturers turn to work order automation

Manufacturers turn to AI-powered work order automation software to give an impetus to manufacturing efficiency and sustainability minimizing environmental impact.

In 2025, several trends, such as AI, IoT, and automation, are converging to reshape the industry. With the growing emphasis on sustainability and remote monitoring, this year calls for rethinking how facilities operate and care for their occupants.

Key Benefits of AI & IoT in Sustainable Manufacturing

The convergence of AI and IoT delivers measurable, multi-dimensional benefits to manufacturers seeking sustainability:

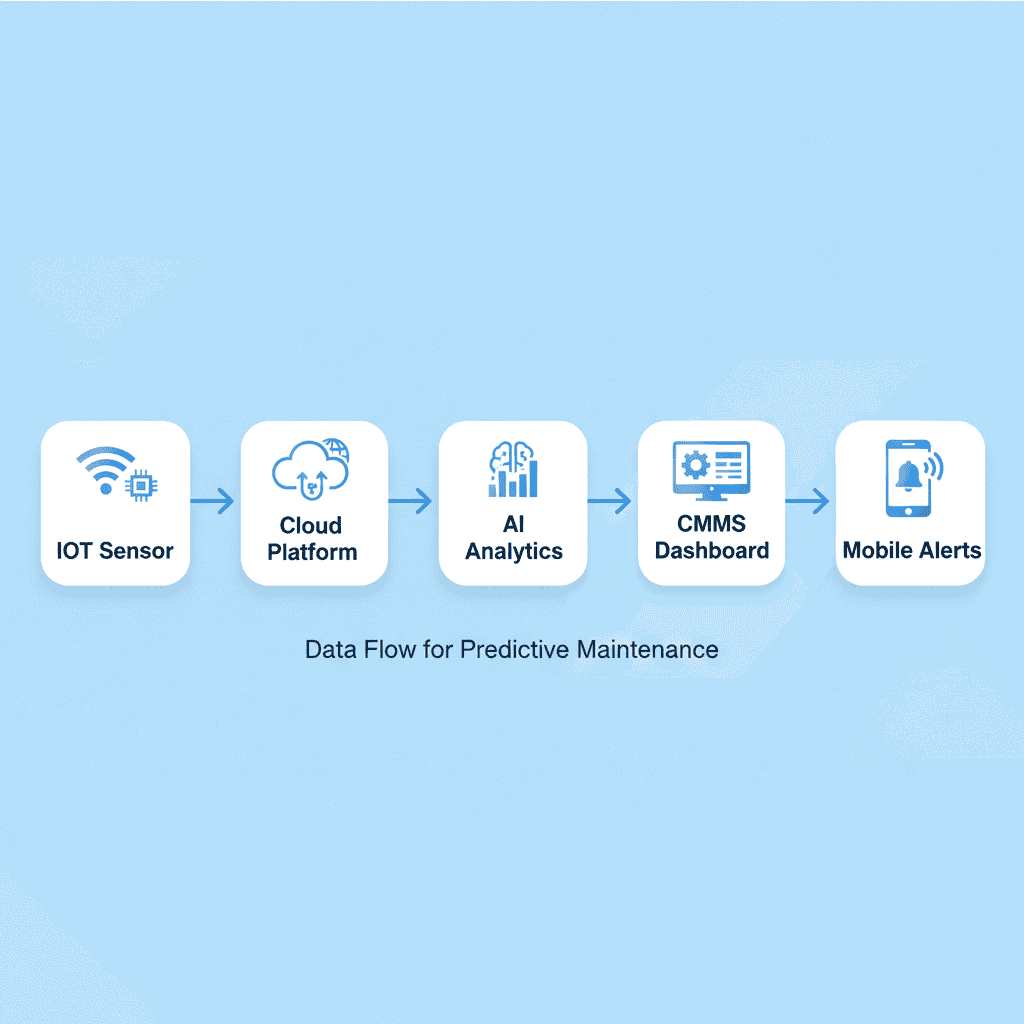

1. Predictive Maintenance

IoT sensors continuously capture data from motors, pumps, and critical assets. AI algorithms analyze this information to forecast potential failures, preventing costly breakdowns and minimizing downtime. This not only reduces waste but ensures optimal resource utilization.

2. Asset Lifecycle Management (ALM)

With AI and IoT, manufacturers gain deeper visibility into every stage of the asset lifecyclefrom acquisition and usage to maintenance and decommissioning. Prolonging the useful life of machines reduces replacement costs, conserves raw materials, and drives long-term sustainability.

3. Energy Efficiency

Smart energy monitoring allows companies to track and control electricity, compressed air, water usage, and HVAC systems. Automated triggers can switch off high-consumption devices during idle times, leading to significant cost and energy savings.

4. Carbon Emissions Reduction

AI-powered analytics provide automated carbon footprint reporting, making compliance with environmental regulations easier and more accurate. Manufacturers can set carbon reduction targets and monitor progress through real-time dashboards.

5. Worker Safety

IoT sensors can detect unsafe conditionslike rising gas levels or poor air qualityand trigger alerts instantly. AI tools enhance safety further by predicting high-risk scenarios and helping facility managers design preventive measures.

AI-based Asset Management Software

An AI-based Asset Management Software is a powerful tool with integrated smart technologies like IoT and AI that support Asset Lifecycle Management (ALM), from procurement, installation, usage, and maintenance to decommissioning.

IoT devices sense the environment, alert concerned stakeholders on the reach of alarming environmental conditions and resource consumption, and provide useful recommendations to minimize resource consumption and extend the shelf life of assets.

Manufacturers who embrace sophisticated and practical tools will lead the way in achieving sustainability, laying a solid foundation for long-term success in a rapidly evolving industry landscape.

The Role of AI & IoT in Predictive Maintenance

IoT plays a vital role in predictive maintenance—a cornerstone of ALM. IoT has indeed revolutionized asset monitoring by offering real-time data on energy consumption, equipment performance, and resource utilization from sensors mounted on machinery.

Shift supervisors can collect the values for parameters required for Overall Equipment Effectiveness (OEE) calculation automatically with IoT technology. AI analyzes this data to predict maintenance needs and optimize resources. To cite an example, motion sensors can detect movement over a pathway using passive infrared sensors and turn on the lights automatically.

Manufacturers can track downtime automatically, predict failures, and optimize production schedules. This precision reduces waste, conserves energy, and ensures that assets operate at peak efficiency.

By analyzing vibration patterns, temperature fluctuations, and historical performance data, IoT-enabled systems can warn technicians of nearing equipment failures that do not show any obvious signs of failure beforehand.

This approach not only prevents costly unplanned downtime but also reduces the environmental impact of inefficiencies.

Real-World Use Cases

While AI and IoT may sound futuristic, their impact is already visible across industries:

- Manufacturing Plants: Vibration and temperature sensors installed in motors detect anomalies long before visible signs of failure. Automated alerts trigger maintenance work orders, minimizing downtime and ensuring uninterrupted production.

- Pharmaceutical Industry: Cleanroom compliance is vital for drug manufacturing. IoT sensors continuously monitor humidity, air quality, and particle levels, while AI ensures deviations are flagged instantly, protecting both regulatory compliance and product safety.

- Oil & Gas: In this high-risk sector, predictive analytics powered by AI can detect early signs of pipeline leaks or pump failures. By acting on predictive insights, companies prevent costly accidents, reduce environmental hazards, and improve worker safety.

- Automotive Manufacturing: Smart automation systems powered by IoT track robotic assembly lines for energy usage and efficiency. AI models suggest optimized schedules to reduce power consumption while maintaining throughput.

These examples show that AI and IoT are not “nice-to-have” technologies they are strategic enablers of sustainable growth.

Work order management and GenAI

It is a pathetic sight to see maintenance managers struggle to assign proper failure codes to manual work orders and identify the root cause of issues. A digital solution eases the process with quickly developed low-code solutions.

Regular inspections are an intrinsic part of Asset Lifecycle Management(ALM) for the assets to operate error-free and efficiently.

AI-based triggers of maintenance schedules can be done based on energy consumption patterns, air pollution levels, pH levels of drinking water, etc. All these triggers can be achieved without human observation or intervention.

Such intelligence in resource conservation and selective triggering of schedules based on needs is a critical aspect of sustainability. GenAI a subset of AI helps facility managers compose standard operating procedures very quickly based on the defined tasks.

Smart automation systems, whether AI-powered or not, can help track and optimize energy use in real-time. For example, adding IoT-enabled components can make older machines smarter and more efficient, extending their useful life and reducing the need for replacements.

Future Trends: GenAI & Digital Manufacturing

The next chapter of sustainable manufacturing is being written through Generative AI (GenAI), digital twins, and Industrial IoT.

Generative AI (GenAI): Maintenance managers often struggle with documentation and standard operating procedures (SOPs). GenAI tools can automatically generate SOPs, inspection checklists, and even suggest optimized workflows based on predefined tasks. This reduces manual effort and accelerates adoption of best practices.

Digital Twins for Energy Modeling: Digital twins virtual replicas of physical assets are being increasingly used to simulate production processes. By modeling energy usage, manufacturers can experiment with different operating conditions and identify the most sustainable configurations before implementing them in the real world.

Industrial IoT at Scale: While many factories currently use IoT for asset monitoring, the next wave involves scaling Industrial IoT across entire plants, supply chains, and ecosystems. This enables unified sustainability tracking, from raw material sourcing to final product delivery.

Integrated CMMS Dashboards: Sustainability metrics like energy usage, emissions levels, or resource efficiency will soon be integrated into Computerized Maintenance Management System (CMMS) dashboards. This ensures that facility managers can monitor production health and sustainability KPIs side by side, in real time.

By embracing these trends, manufacturers not only future-proof their operations but also position themselves as leaders in green, digital manufacturing.

Measuring the Impact of Sustainability Initiative

Quantifying sustainability has been a long-standing challenge for manufacturers. IoT systems provide a wide variety of key sustainability metrics, such as energy consumption, soil moisture, wind speed, emissions levels, water flow rate, etc.

These insights provide a clear and vivid picture of the systems in manufacturing facilities. It makes regulatory compliance, reducing carbon emissions, and audits a breeze.

Manufacturers aiming to stay competitive and sustainable must focus on adopting strategies like ALM, IoT integration, and digital work order automation systems.