A guide to Risk-Based Maintenance for Optimized Equipment Uptime

Unplanned downtime eats into business profits. Studies unveil the fact that unplanned downtime costs as much as $250,000 per hour and reduces productivity by a whopping 20%! Risk-Based maintenance can play a central role in reducing downtime significantly.

Risk-Based Maintenance (RBM) is an advanced maintenance management strategy designed to minimize equipment failure, extend asset life, and reduce costly unplanned downtime. By prioritizing mission-critical assets, organizations can maximize uptime while optimizing their maintenance budget.

What is risk-based maintenance?

Risk-based maintenance involves identifying mission-critical and highly productive assets and dedicating special maintenance efforts and resources. It is a productive approach toward maintenance management and business profitability.

Why is Risk-based Maintenance Important?

Risk-based maintenance plays a pivotal role in improving equipment uptime. It involves directing focus and maintenance efforts on business-critical assets rather than spending time and energy wastefully on maintaining equipment that doesn’t deserve it.

Benefits of Risk-Based Maintenance in Maintenance Management

- Reduced unplanned downtime through predictive alerts.

- Higher equipment uptime for mission-critical assets.

- Optimized maintenance budget allocation.

- Stronger compliance & safety monitoring.

Which organizations require risk-based maintenance?

A risk-based maintenance approach works for your organization if it:

- Houses robust and bulky equipment that is highly expensive to replace.

- Operates in a limited maintenance budget or maintenance resources.

- Has assets deployed in remote locations posing practical difficulties in maintenance.

- Cannot replace or substitute the failure of mission-critical equipment.

Risk based maintenance framework

Apply a risk-based maintenance framework to each equipment and system in your facility. Let’s consider an HVAC system in a beauty salon for example.

The facility is responsible for maintaining a cool temperature, and reasonably good air quality in a clean room environment.

Let’s apply a Risk-Based Maintenance Framework to a Salon’s AC System.

1. Identification of mission-critical equipment

The Air Conditioning unit is crucial for keeping clients comfortable and the makeup intact. Hence it requires more maintenance attention compared to other physical assets.

2. Assess Interconnected Systems

The AC system may interact with ventilation fans and air purifiers, which play a role in maintaining air quality and temperature.

3. Identify Likely Failure Modes

Potential failures are:

- Air Filter clogging, causing a significant reduction in cooling.

- Compressor issues, triggering loss of cooling.

- Fan malfunctions, causing uneven cooling.

4. Associate each failure mode with a probability of failure

– Air Filter Clogging: The failure rate is relatively high but has low consequences if handled early. Schedule filter checks based on usage and dust accumulation.

– Compressor Issues: The probability of failure is medium if the AC unit is brand new. It can cause potential discomfort for clients. Schedule seasonal checks to avoid sudden breakdowns.

– Fan Malfunctions: Low likelihood of failure. The impact is less severe compared to compressor issues. Regular inspections help catch early signs of wear.

By analyzing and prioritizing maintenance tasks based on risk, salon managers can ensure a comfortable environment for customers and avoid disruptions during peak hours.

Real-World Applications of Risk-Based Maintenance

- Manufacturing: Vibration sensors detect motor faults before failure.

- Pharma: IoT monitors cleanroom conditions to avoid compliance issues.

- Oil & Gas: RBM predicts leaks + optimizes asset maintenance strategies.

How to Implement Risk-Based Maintenance

As illustrated in the pictorial representation, conducting a risk-based maintenance consists of two main parts:

1) Performing a severity analysis

Severity is a measure of an asset’s importance to the organization. For example, in an Information Technology company setting, failure of generators and centralized air conditioning units have much higher criticality than faulty general building infrastructure.

Evaluate the effect of asset failure on the organization as illustrated in the severity matrix below. Rank failure modes based on various facets such as safety, production, and cost.

As we know there are multiple ways an asset can fail. Each failure mode may be associated with varying degrees of risk. Rate the failure modes based on your own severity matrix.

| SEVERITY MATRIX | SEVERITY | |||

| CATEGORY | Trivial(1) | Moderate(2) | Severe(3) | Critical(4) |

| Health hazard | Minor injuries-no treatment required | Injuries requiring treatment in outpatient ward | Injuries requiring hospitalization | Grievous Injuries that pose threat to life |

| Equipment damage | Negligible | Easily rectifiable | Major repair,may affect nearby equipment | Causes equipment destruction |

| Production impact | Minor halt | Halt acceptable to a certain extent | Long halt | Prolonged halt causing heavy production losses |

| Cost | Less than $100 | $101-10,000 | $10,001-50,000 | Greater than $50,001 |

You rate failures on a severity scale of 1 to 4. Arrive at Asset Severity Index(ASI) by multiplying the score in each category (or) adding the scores (or) simply taking the highest score in any category.

Irrespective of the way you calculate the Asset Severity Index, a higher score means the asset is more critical to business, relative to the other assets. Record these scores.

2) Performing a risk assessment.

Collect asset data such as:

- Unique Identity

- Acquisition cost

- Age

- Mean Time Between Failure (MTBF)

- Mean Time to Repair (MTTR)

- Cost of unplanned downtime

- Frequency of maintenance

All the above information can be inferred either directly or implicitly from a computerized maintenance management system (CMMS) software. If you are interested in the KPIs a CMMS displays in its Dashboard read the blog.

The operating environment of an asset is important for assessing the risks. Consider the classic example of a light pole installed on the terrace or exterior walls. It is more prone to corrosion than its counterparts installed inside the building. Assets installed in moist or dusty places may call for frequent inspections and cleanup.

You should also factor in the average repair cost of an asset, hours lost each year in downtime (production loss) owing to equipment malfunction, accident history, safety hazards, etc.

3) Devise Maintenance Strategies

Once risks are identified, devise maintenance strategies appropriate to the assets in the risk profile, present condition, and anticipated usage.

Set maintenance schedules with frequent inspections, predictive maintenance, and condition-based monitoring, for mission-critical assets.

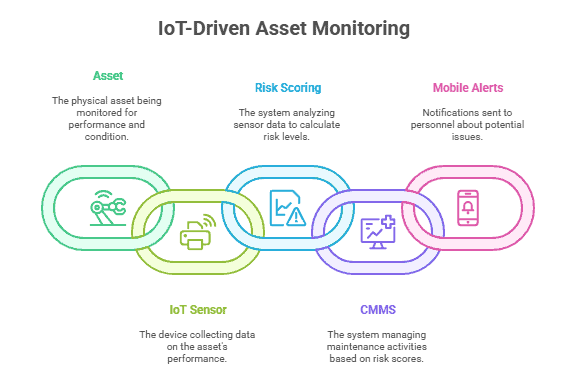

Yes, it is IoT-powered predictive maintenance and not just preventive maintenance which is an old concept. For those interested in knowing more about IoT-based maintenance and solutions please click here.

For instance, in manufacturing, vibration and temperature sensors can alert you via the mobile app when these parameters fall outside the normal range, hinting at a need for maintenance.

After you address approaching failures with mission-critical assets, your team can shift the focus to assets of secondary importance.

4. Train Your Team

Sensitize your maintenance team and default asset users on the importance of implementing a risk-based maintenance strategy. They’ll need exposure to IoT-powered predictive tools and prioritization of maintenance tasks productively.

5. Monitor and Adjust

RBM is a continuing maintenance strategy. Continuously monitor equipment performance and tweak your maintenance strategies as per business objectives. This will help in the continuous improvement of outcomes.

How Risk-Based Maintenance Fits Into Modern CMMS

- RBM works best when integrated with CMMS software.

- CMMS enables asset health tracking, predictive maintenance, and digital proof of maintenance.

- AI + IoT integration makes RBM execution scalable.

Final Takeaways

Go for a risk-based maintenance strategy confidently if your business deals with highly critical machinery indispensable for your daily operations. Risk-based maintenance is highly recommendable for facilities housing heavy equipment with huge replacement costs. The obvious benefit is that it handles maintenance cost-effectively, allocating the resources only where needed. Make a wise move towards managing your critical assets better. While time based maintenance still plays a role in many preventive maintenance schedules, shifting to a risk-based model can result in more cost-effective and targeted interventions.